Monoclonal antibodies are extensively used in research laboratories, diagnostic products and immunotherapy and have multiple advantages over polyclonal antibodies. They exhibit enhanced specificity to single epitopes, have little or no variability, and are easy to modify and customize as required.

The History of Monoclonal Antibodies

In 1984, Georges Köhler, César Milstein, and Niels Jerne received the Nobel Prize in Physiology and Medicine for their exemplary work on monoclonal antibodies. Their work laid the foundation for large-scale commercial monoclonal antibody production using hybridoma technology. This technology involved injecting laboratory mice or rats with an antigen against which a monoclonal antibody is desired. B-cells producing the desired antibodies are isolated from the splenocytes of the immunized animal. Fusion of those B-cells with myeloma cells yields hybridomas (immortalized cells producing the desired antibody). After a careful selection and screening process, the hybridoma cells are grown on a large scale. Historically, selected hybridoma cells were injected into the peritoneal cavity of mice where they induced production of an antibody-concentrated fluid called ascitic fluid.

In Vitro Monoclonal Antibody Production

Increased focus on ethical animal handling eventually created a demand to move away from animal-derived antibody production methods. This led to the development of in vitro techniques for antibody production where hybridoma cells are grown in cultures under carefully regulated conditions. A variety of mammalian cell lines and bacterial strains have also been genetically engineered to express antibodies. Such in vitro techniques are more ethically acceptable than the animal-based techniques. There are, however, a number of challenges with in vitro monoclonal antibody production.

Challenges with in Vitro Monoclonal Antibody Production

- Low yield: In vitro production cultures often yield less antibody/ml than the in vivo ascitic fluid method.

- Cell death: Maintaining optimal cell growth and viability is essential for high antibody yields and an optimized process.

- Contamination: In vitro production cultures are subject to risks of contamination associated with long-term cell cultures.

- Time-consuming: In vitro production cultures often have to be maintained over a long period of time in order to yield desired quantities of antibodies.

- Scalability: Translating research scale antibody production to large-scale commercial production can be difficult. Therefore, one must consider scalability of process when optimizing a production process.

- Cost: Components of in vitro production systems (such as equipment, consumables, and media formulations) can be very expensive.

Overcoming Challenges

These challenges can be overcome by using the following optimization strategies:

1. Optimizing Cell Lines

Although traditional hybridomas (mouse/rat B-cells fused to myeloma cells) are commonly used for the production of research antibodies, human therapeutic antibodies are most often cloned into and produced by recombinant cell lines. The choice of cell line heavily influences the success of the antibody production process. Optimizing recombinant cell lines is often the most time-consuming step in antibody production and requires careful consideration of a number of factors:

- Cell line origin: Mammalian cells are the best choice for producing most recombinant proteins because they yield the most therapeutically suitable antibodies. Approximately 70% of all recombinant proteins produced today are made in Chinese Hamster Ovary (CHO) cell lines.

- Use of host cell line variants (e.g., CHOK1 suspension variant) and engineered cell lines: Recombinant cell lines can be engineered to modulate glycosylation and other post-translational modifications, to reduce cell death via the introduction of anti-apoptotic genes, to develop inducible systems to decouple the growth stage from the production stage, and to produce antibodies with greater affinity and higher yields.

- The right gene expression vector: Mammalian expression vectors contain cassettes for antibody genes and selection markers as well as strong promoters and enhancers. One can add additional sequences for better signaling, export, and secretion of protein as required.

- Optimal transfection method: Several transfection methods exist, including calcium-based transfection, lipofection, electroporation and polymer- or dendrimer-based transfection.

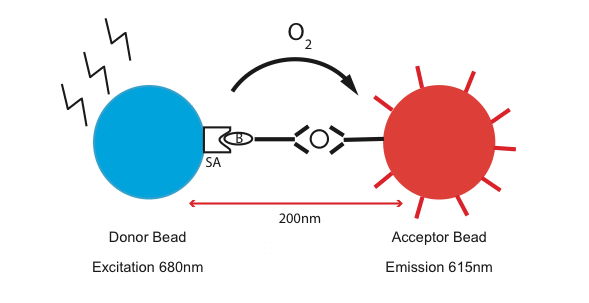

- Clone screening method: A reliable screening method is essential to identify the most productive clone and an estimate of antibody quantity and quality.

2. Optimizing Culture Media Conditions for Production of Monoclonal Antibodies

Whether you use traditional hybridomas or recombinant cell lines, the choice of culture media influences cell growth and, thus, antibody quality and yield. Laboratories often test a number of different media compositions for the cell line under investigation to identify the optimal one. The factors below are the most important considerations concerning the culture media.

- Media formulations that include animal serum are generally not acceptable for human therapeutics. Therefore, serum-free, chemically-defined media should be used to avoid co-purification of animal-derived products with antibodies.

- The addition of various additives and nutrients can enhance the production of monoclonal antibodies in vitro. Supplements may include growth factors, growth inhibitors, autocrine factors, and cyclic nucleotides. Current production processes with recombinant cell lines often include additives that modulate post-translational modifications (e.g., glycosylation or fucosylation) which are important to the functionality of antibodies. Certain additives also aid in higher production yields.

- High osmotic pressure may stimulate antibody production in certain cases. One can investigate this by testing different salt and sugar concentrations in the culture media and selecting those that result in the best antibody yield.

- A basal medium with reduced glucose and glutamine concentrations prevents the build-up of certain undesirable metabolic by-products, such as ammonia and lactate, and therefore leads to prolonged cell viability.

- Amino acids in the media act as a preferential energy source for cell metabolism, leading to increased monoclonal antibody output and reduction in the cells’ reliance on carbohydrates for energy.

- Because certain cell lines have different requirements for their growth and production phases, consider a two-media strategy where the cells are cultured in a medium optimized for growth and then switched to another medium optimized for protein production. However, this approach could increase the complexity and cost of the system.

- Determine and define standardized physicochemical culture conditions (such as pH, temperature, O2 and CO2 levels, and aeration capacity) for optimal media performance and enhanced antibody production.

3. Optimizing Monoclonal Antibody Production Systems

You can overcome challenges with low yield, scalability issues, higher processing times, and process optimization by choosing the right production system.

Large scale production can be done either in batch, perfusion, or continuous culture systems.

- Batch culture: All nutrients are supplied in the beginning as a base medium and every batch is separately processed.

- Continuous or fed-batch culture: Nutrients are added as they are consumed so that the process runs on a continuous basis.

- Perfusion culture: Nutrient medium is circulated throughout the culture through semi-permeable membranes. In this system, the cells can be immobilized on a solid support matrix or retained in hollow fiber filters.

The right process type depends on the scale of production, available resources, and the amount of antibody required. Laboratory-scale antibody production for research purposes is possible in spinner flasks, roller bottles, culture bags, or small bioreactors as batch culture systems. These processes are simple, fast and economical and require minimum human interference.

Fed-batch or continuous systems usually use larger bioreactors and give an enhanced yield because of the higher cell densities that can be achieved. They use less media, but the process is longer and the equipment is complex, expensive, and requires greater monitoring.

Use of the perfusion method requires high capital investment in terms of space and equipment, so this method is well suited to large industrial-scale production units. This method offers the highest yield and is optimal in terms of time investment, energy usage, and efficacy. However, it requires continuous monitoring, timely sample collection, and tight control over operations.

Other Options for Antibody Production

Though the process seems long and daunting, it is crucial to optimize every step to meet the ever-increasing demand for therapeutic and research antibodies. However, another option is available. Antibody companies offer in vitro antibody production services. For example, QED Bioscience has a proprietary medium that enhances antibody production in vitro. Using a company that has expertise in in vitro antibody production can provide you with quality antibodies and relieve you of the time and expense required to develop optimal production processes.

Whether monoclonal antibodies are produced in vitro in-house or by a company, advances in bioprocess development, media formulations, and cell line engineering make it faster and easier to optimize in vitro antibody production processes.

Further Reading

1. Loo L, Robinson MK, Adams GP. (2008). Antibody engineering principles and applications. Cancer J. 14(3):149-53.

2. Jiang, Z. 2012. Fed-Batch Cell Culture Process Optimization. BioProcess Int. 10(3):40-45.

3. Skaletsky E, Tucker E, Maggio E. (2013). Enhancing antibody production. BioProcess Int. 11(10):54-58.

4. Nishimiya D. (2013). Proteins improving recombinant antibody production in mammalian cells. Appl Microbiol Biotechnol. 98(3):1031-42.

5. Li F, Vijayasankaran N, Shen AY, Kiss R, Amanullah A. (2010) Cell culture processes for monoclonal antibody production. MAbs. 2(5):466-79.

6. Costa AR, Rodrigues ME, Henriques M, Azeredo J, Oliveira R (2010). Guidelines to cell engineering for monoclonal antibody production. Eur J Pharm Biopharm. Feb;74(2):127-38.