Did you know that most centrifuge accidents result from user error and improper centrifuge care? [1]

That’s right, we really are the problem!

Many a machine has been destroyed by an unsuspecting scientist who is just in it for the pellet. Even worse, the more expensive the machine, the more sensitive it is, and therefore the easier it is to break!

Does your centrifuge sound like an overly aggressive car engine when turned on?

We know that a centrifuge needs to be balanced, but what else can we do to give these pricey monsters a long, successful tenure in the lab?

Here are five simple and easy-to-follow tips to keep that centrifuge alive!

5 Tips for Maintaining Your Centrifuges

1. Fully Attach the Rotor

After gently placing the rotor on the drive shaft, I always try to lift it to ensure it’s not loosely attached. A spinning rotor that isn’t fully attached can quickly turn into a weapon, destroying the inside of the machine.

Broken centrifuge = broke PI = get ready to start sterilizing and reusing gloves and pipette tips!

2. Keep Your Centrifuge Below Maximum Speed

The maximum speed of your sweet new centrifuge is 26,000 rpm! You pop in some tubes and begin to centrifuge at 26,000 rpm for 20 minutes while grabbing a quick lunch. When you get back to the lab, your lab mates are huddled around the broken centrifuge.

You: Why is this happening to me?

Centrifuge Company: Because you’ve gone over the max speed.

You: But I didn’t intend to! I specifically made sure that I was at 26,000 rpm!

Centrifuge Company: What was the density of the solution you centrifuged?

You: *freaked out silence*

If the solution you are spinning has a density above 1.2 g/mL, the centrifuge should be run at a lower speed than the max. That’s because maximum speed plus the tubes and solution puts too much strain on the rotor. If you want to find the real maximum speed to use based on a solution’s density, use this formula:

reduced maximum speed = (70,000 rpm) \sqrt[]{(1.2g/mL)/\rho}

where \rho = density.

3. Keep Your Centrifuge Clean From Hazardous Spills

Rotors are often made of steel or aluminum. They are subject to corrosion with all the washes, spills, and leaks that they go through in a lifetime. Rotors are protected from corrosion by an anodized coating.

Washing the rotor with a simple solution of soapy water is necessary, but washing with strong acids and bases and lab detergents can wear the anodized coating off, exposing the rotor to rust. Rusty rotors, while a good band name, are damaged goods and should not be used, so stick to a solution of mild detergent to keep your centrifuge happy!

4. Use the Right Tubes

If, for some reason, your tubes break, melt, or disintegrate during centrifugation, samples will leak and throw the delicate balance off. This can mean a damaged rotor or bits of tube flying around wreaking havoc; remember that a small mass with all that centripetal force can cause serious damage.

Before putting tubes in the rotor, it’s important to consider:

- Can the tubes you’re using withstand the temperature you want to centrifuge at?

- Can these tubes safely hold the solution in them? For example, plastic tubes will fall apart when there’s chloroform in the solution. It’s therefore important to consider what kind of solution is being centrifuged.

- Do the tubes need to be filled completely? Some tubes crush in if not filled completely (e.g., heat-sealed tubes).

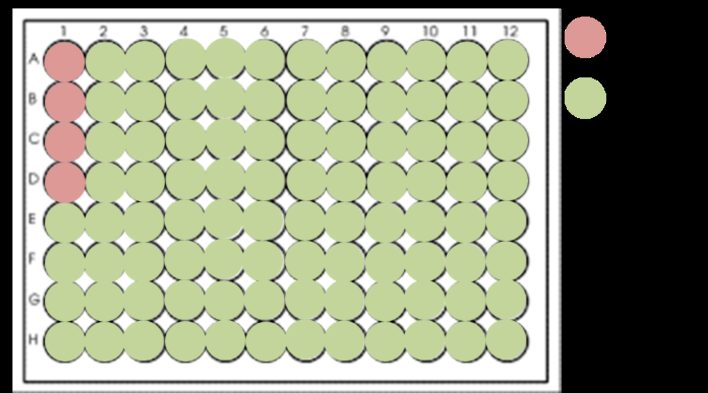

Keeping a user log next to the centrifuge is one way to ensure you and everyone else in the lab is sticking to using the correct tubes. Have everyone fill out when and how they used the centrifuge—this will give everyone a second to pause and consider if they are using the right tubes! You could also have a checklist with this that explicitly states to check the tubes are correct (and what the correct ones are!).

5. Take Advantage of Free Resources

Read the manual before centrifuging and attempting to fix anything. If you’re unsure what to do, call for help. If your institution doesn’t already have someone on staff to handle centrifuge problems, many manufacturers will send a professional to take care of it for you.

Final Word on Centrifuge Care

Read more from Bitesize Bio to learn other important centrifuge safety tips, including balancing tubes and ensuring all the buckets in a swing bucket rotor are in place before you start your centrifuge. Or watch our handy webinar on the essentials of centrifugation.

For more tips, tricks, and hacks for getting your experiments done, check out the Bitesize Bio DIY in the Lab Hub.

Originally published November 2016. Reviewed and updated February 2023.

References

- Esco Life Sciences. Safety Tips on Centrifuge Operation. Accessed 31 August 2022