In the previous articles in this series, we have shed light on the use of Thin Layer Chromatography as a qualitative technique to separate compounds from a mixture. We have also read the basics and instrumentation of High-Performance Thin Layer Chromatography (HPTLC) which is a highly precise and quantitative variant of TLC. After going through the ‘hows’ and the ‘whys’ of HPTLC, let us look at its ‘dos’ and ‘don’ts’ – in order to achieve precise and error-free results, as well as to avoid false positives.

Let us go through each of them from start to finish:

1. Do Use Specific HPTLC Plates

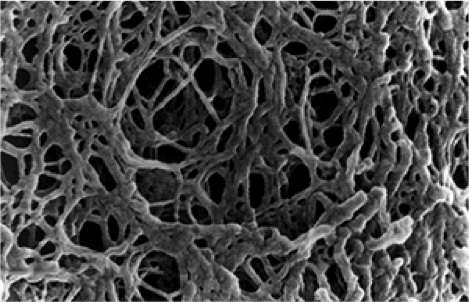

Use HPTLC plates instead of conventional TLC plates. Why, you ask? Because HPTLC flourished from developments in the quality of sorbents, consistency of plate manufacture, plate development procedure, application of detection (derivatization) reagent, scanning procedure, and equipment for sample application. HPTLC plates have thinner layers and are made using smaller silica particles (?10 µm). Moreover, the particle size distribution over the plate is narrower than that for a conventional TLC plate. Hence, HPTLC plates offer advantages such as greater resolving power per unit distance, faster development and reduced consumption of the solvent system.

2. Don’t Be Careless When Handling Syringes

HPTLC syringes are a costly business. Always be careful while handling those. Load your sample in the syringe (manually), and check if there are any air bubbles (bubbles in the syringe mean the wrong volume was loaded, leading to false positives). If there are any bubbles, just hold the syringe in an upright position and purge the bubbles out of it.

3. Do Ensure Proper Solubilization of Samples

While preparing HPTLC samples/standards, make sure that the solvent you are using solubilizes the sample completely (a completely soluble sample will form a homogenous mixture with the solvent without any noticeable precipitate). Also, always filter the sample through a 0.22 µm syringe filter to remove any coarse particles/precipitate that might clog the HPTLC syringe.

4. Do Activate the Plate Prior to Use

Silica is hygroscopic and hence HPTLC plates absorb water when exposed to air. Activate the silica plate by heating it in the oven to remove the water.

What if the plate is used without activation? Your results could get affected in a variety of ways depending on the nature of your compound and/or the solvent system. For instance, if the compound is polar, it might remain tightly bound to the silica and affect its Rf value. Also, if the solvent system is highly non-polar, it might fail to penetrate the silica properly, ultimately affecting the movement of the sample (Note: Do not touch the plate surface to avoid getting any residues from skin oils or dirt on the plate. Contaminated plates may lead to false signals during scanning. Either hold the plate at the edges, or with a clean pair of forceps).

5. Don’t Load Your Plate Absent Mindedly

The autosampler has X and Y axes labeled on its platform. Place your plate aligned with these axes, such that the sample band application occurs on the X-axis and runs along the Y-axis.

6. Do Keep the Position and Width of the Bands Constant

The position of the bands for a particular compound decides the ultimate Rf value. Hence to get a constant Rf every time, make sure you don’t change the orientation of the sample application from the X and Y-axis. Also, the width of the sample band application must remain constant as it is a direct measure of band intensity and hence the quantity of the compound. All of this information is to be fed in the computer software that commands the HPTLC autosampler.

7. Do Ensure You Properly Dry the Plate After a Run

Once the plate has been run in its respective solvent system, always dry it before dipping in a derivatization agent, as the compounds from wet bands can dissolve when the plate is immersed in the derivatization agent. Air drying plates is extremely time-consuming and hence we use a blow-dryer to dry the plates quickly after the run.

8. Do Be Careful When Developing the Plate

Do not keep the plate immersed in the derivatization agent for too long, as it can lead to the dissolution of the compound in the solution. We usually dip it for a few seconds, which is enough to get the plate soaked completely and evenly.

9. Don’t Change Heating Time and Temperature of the Oven

You might come across compounds that cannot be detected visually or with the scanner either. Sugars, for example, need to be charred by dipping in a sulphuric acid solution prepared in water and then heated. The amount and time of heating greatly impact the intensity of bands. Hence, keep the time and heat constant every time you analyze a given compound.

10. Do Not Use a Hot Plate for HPTLC

You can use a hot plate to develop TLC plates as it is not a quantitative analysis. But with HPTLC, you need to make sure that the distribution of heat is even. A hot plate is unable to distribute heat evenly and some bands of your sample will be heated at a higher temperature, and hence the intensity of the response recorded by the scanner would be higher. Furthermore, although less likely, if the plate has any bends/curves across its length, it might not come in contact with the hot plate surface evenly, leading to localized zones of heating. Instead, either use an HPTLC plate heater or an oven with a controlled temperature. Make sure you use the same mode of heating throughout your experiments to ensure the accuracy and reproducibility of your results.

With these things in mind and a little practice with handling HPTLC, you will certainly find it to be a very convenient method of analysis.