In part one, I discussed the ‘how to’ of simply freezing samples and the basics of vacuum evaporation, often referred to as speed vacing. Now, we’ll have a look at two more complex sample storage techniques (at least in terms of equipment) for drying samples (lyophilizaton and rotary evaporation) and the simpler method of blow down drying.

Lyophilization (also called freeze drying)

Lyophilization is perhaps my favorite because of the fluffy white powder you get at the end and the stability of the resulting macromolecules. It also relies on sublimation (see Figure 1), which is when a solid turns to a gas without going through a liquid phase. I find this a magical concept! Lyophilization is a versatile method that can be used to store macromolecules such as proteins, lipids and DNA, microbes like bacteria and yeast and, if you take enough care and can tolerate some loss in viability, mammalian cells. The physics and chemistry of lyophilization can be very particular and dependent on the type of sample. Below I describe the most basic aspects for aqueous solutions that can be frozen solid.

To lyophilize a sample in an aqueous solution, freeze it overnight at –80°C. The smaller the volume, the faster the process, but it should be no larger than 35% of the vessels capacity (e.g. 17.5 ml max for a 50 ml tube). You can place the sample at an angle when you freeze it to increase the surface area.

Once your sample is frozen, place it on ice and quickly cover with parafilm; remember to poke some holes in the film. Place the tube into the freezing flask and load it onto the lyophilizing machine. It sounds obvious but make sure you know how to run the machine, especially when turning off the vacuum to collect your sample at the end of the process or you’ll risk your sample being sucked up just like Augustus Gloop in the chocolate river. If you don’t get that reference, read Charlie and the Chocolate Factory while you wait for your sample to be ready – a few hours to overnight plus a few hours. To check that your sample is fully lyophilized, you can take out the tube and shake it gently. Any ice that remains will clink audibly, in which case you need to put it back on the machine – before it melts! Once your sample is dry, it does not matter if you are not there to take it off the machine right away. It’s quite happy sitting under vacuum. If in doubt about complete dryness, leave it on!

The above description applies to samples that can fit in a 1.5–50 ml tube. If you have a larger sample, you may need to use shell freezing. Shell freezing involves rotating the flask containing your sample at an angle while it is held partially submerged in methanol mixed with dry ice or in liquid nitrogen. As the flask rotates the contents spread over the surface of the flask, increasing the surface area and freezing it layer by layer. Increasing the surface area increases the speed of freeze drying. You may also need to use a cryoprotectant but again this depends on your sample.

For a much more detailed description of lyophilization, go here.

Rotary (and Vortex) Evaporation

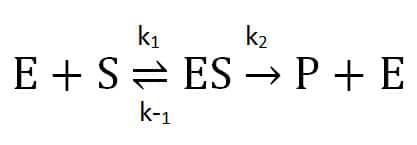

I think of this as hot drying in analogy with shell freezing followed by freeze-drying. Instead of freezing the sample under rotation and then applying a vacuum, the sample is heated under rotation while a vacuum is simultaneously applied (Figure 2).

Heating is done by partial submersion of the flask in a heated water bath. A vacuum is applied to lower the boiling point of the solvent, which has the advantage of keeping your sample cool too. As the solvent boils, the evaporated solvent filters up through a cold trap and condenses into a collecting reservoir. Rotation spreads the sample over the surface of the flask and accelerates evaporation.

The boiling temperature of the solvent under a certain vacuum strength and the amount of heat applied to the sample will determine how fast drying occurs. It is possible to make the boiling temperature so low that evaporation occurs when the temperature is too low for condensation to occur in the cold trap. The conditions used will depend on your sample and the solvent. A detailed description of setting up for rotary evaporation can be found here.

A rotary evaporator is generally used for single larger samples. A vortex evaporator uses the same principles, but instead of rotation, the samples are vortexed. This is not like the little vortex machine you might have on your bench for vigorously mixing samples. Instead, it rapidly swirls the tubes sitting in a heated block to create a vortex so that your sample remains at the bottom of the tube during evaporation – a bit like vacuum evaporation, described in part 1. Several samples can be processed at once.

Blow Down Drying

This involves blowing an inert gas (usually nitrogen) at your sample until the solvent evaporates (Figure 3).

It’s not much good with solvents, such as water, that have low volatility. This limits the sample type if you need it for more than analysis – most proteins don’t survive well in organic solvents, for example. Additionally, it needs to be monitored to watch for dryness and if you aren’t careful and blow too hard, your sample will be splashed onto the sides of the vessel making it harder to recover, thus reducing yield (arghhh!). Special tubes with a teat at the end can be purchased to help collect the sample at the bottom of the tube. Some cooling of the sample occurs first, because as the gas goes from the high pressure inside the tank to atmospheric pressure in the room (adiabatic cooling) and second, because evaporation itself is cooling. Think of the lovely cooling effect of sweat! To speed up drying, you can gently heat your sample on a heat block. I’ve used blow down drying for lipid fractions because it’s cheap, I could do it in a fume hood and it requires little equipment apart from a nitrogen tank, regulator and rubber tubing with a pipette tip on the end.

In summary, samples can be simply frozen (no drying involved), centrifuged while being dried under vacuum, frozen and dried under vacuum, heated and dried under vacuum or blown dry. The method used will depend on the sample type, solvent type and what you want to do with it afterwards. Ultimately it will also depend on the equipment you have available or can scrounge, steal (did I say that?) or borrow.

Let us know if you have any tips of your own in the comments