Sometimes working with a liquid handling machine seems a bit like wrangling a wild mustang—I know what I want it to do, but the software doesn’t work that way. That’s particularly true when working with 96-well plates.

So, sometimes you have to think “outside the box.” Don’t limit yourself to what the manufacturer intended (but do think critically about what you’re doing).

Here are some tricks to get your liquid handler under control.

Pipetting 150 µl With a 100 µl Tip

This one’s tricky and depends on your robot, your situation, and your own personal squeamishness. Say you want to pipette 150 µl of reagent into a 96-well plate. You have 100 µl and 1000 µl tips loaded in the robot; it’s full. If you try to tell Eppendorf’s software to pipette 150 µl, it gives you a size error—150 is bigger than the maximum of 100. You could buy 300 µl tips and load up that spare 300 µl head that’s never been used, but why spend extra money? Instead, you can lasso the beast with what you already have and make one set of tips do double duty.

First, set up program step(s) to pipette 100 µl of reagent without changing tips. Next, set up program step(s) to pipette 50 µl of reagent and this time do let it change tips after the command is finished (assuming that’s in line with your next step). Voila! 150 µl with a 100 µl tip.

Quick Chiller

If your robot has a chiller block (it might look like a metal plate underneath a 96-well plate adapter), it’s a quick and easy way to keep a plate cold while you’re doing something on the bench and there’s no need to remove the plate from the enclosure. I have a one-step program to set the equipment to 4° C and another to turn it off (to avoid wear and tear on the fan).

Make Your Own Fixtures

If by some miracle your service contract and warranty do permit you to make your own fixtures and tools—or if you don’t have a contract—you can have a lot of fun. The idea I had for a new thermo plate was to add a steel plate to the bottom of a tip holder insert. The tip holder insert is already the right size to fit the robot’s deck. All it needs is a little more height and some conductance to work on the robot’s chiller block.

Don’t Let Complex Patterns Beat You

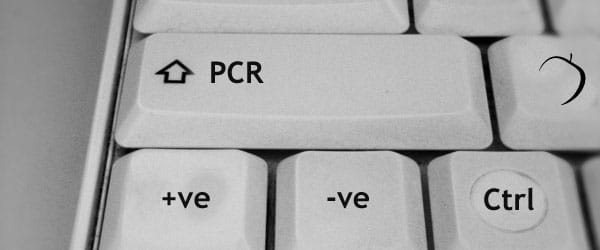

To maximize throughput on our equipment, I run multiple full 96-well plates containing samples from various clients. But invariably there are PCRs that don’t work and I end up repeating them. Now, instead of a nice, full pattern on the 96-well plate, there will be 19 triplicates. I like to keep things organized by client and box, so I might do 7 triplicates in the first trio of columns, 1 in the second, 3 in the third, and 8 in the fourth trio (see Figure below). I plan to set the number of samples to 19 and lay out the dispensing pattern (from microcentrifuge tubes). All is well—except that it isn’t. About halfway through the pattern, the software suddenly considers this pattern “too complex.”

I could move the samples from microcentrifuge tubes to a 96-well plate and do the work with the multichannel pipette, but that’s a lot of work and risk. I could lay out the samples contiguously on the plate, but then I don’t have them organized by client and that’s important to me. To work around the software limitation, I divided the work into four steps. In programming terms for the epClient software, I have a program that includes four logical sections:

- Set the number of samples to 7 and dispense columns 1-3

- Set the number of samples to 1 and dispense columns 4-6

- Set the number of samples to 3 and dispense columns 7-9

- Set the number of samples to 8 and dispense columns 10-12

It does seem like a bit of work, but once I got the hang of it, the small added complexity was well worth it. When juggling a lot of samples and trying to keep them straight, every bit of logic I can add to sample management really helps.

Now you’ve got both some basic and some advanced ideas for working with your liquid handler. Grab a lasso, mount up, and go wrangle that liquid handler!