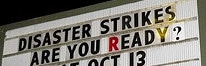

Rookie Researcher Disasters

Wide eyed and wet behind the ears, the rookie researcher steps into the lab for the first time. Armed with several years’ knowledge mined from text books, lectures and undergrad labs he feels ready to take his place amongst the worldwide legions of scientists who battle daily in the pursuit of knowledge. Little does he suspect the pitfalls that lie ahead, the classic mistakes and unknown dangers lie in his path.

Here are four rookie researcher disasters. All are true stories that I have witnessed (and one that I made myself – I’ll let you guess which). Each of you will likely have your own tales to tell, please share them in the comments section below and let this serve as a guide, helping rookie researchers of the future avoid the mistakes of others.

1. Pipette inferno. A pristine set of micro-pipettes hang in their holders above the bench. Tools of precision, and of considerable value. Filled with anticipation, the rookie is performing his first ever culture inoculation. Rightfully mindful of the importance of sterile technique he ignites his bunsen burner and begins the procedure, not yet noticing the smell of burning plastic beginning to permeate the air.

The rookie’s nose twitches, becoming aware of the scent. As the realization crystalizes in his mind, he lunges with growing horror to turn the gas tap off. But it’s too late. An unfortunate positioning of the bunsen burner under his pipettes was his undoing. His pristine micro-pipettes are no longer tools of precision or of considerable value but are now deformed icicles of plastic dripping onto the bench. His first report to his supervisor will not be a pleasant one.

2. Exploding agar. In war zones of the world, an exploding bomb of molten agar and glass would be considered a useful tool. In the confines of a laboratory, I would suggest they be avoided at all costs. This advice comes from bitter experience of being in the lab while a young friend of mine, while dutifully performing his technician duties, proceeded to make up a medium-agar solution in an ordinary (non-toughened) glass bottle. After autoclaving, the lid was tightened and the bottle placed on the shelf for future use, the bomb was primed.

One sunny day, he took the glass bottle and, as per protocol, used the microwave to melt the agar. Crucially however he forgot to loosen the lid and the resulting build-up of pressure caused the unsuitably fragile bottle to shatter, forcing open the door of the (cheap) microwave and spraying glass and molten agar around a 2 metre arc. Amazingly, despite the lab being half full, no-one was caught in the blast zone. This was especially lucky as the microwave was on a shelf at head height – molten agar and glass facial, anyone?

3. Culture flask massacre. An orbital shaker is not the place you would normally expect tragedy to occur. However, a communal orbital shaker using sticky stuff to hold the culture flasks in place… and a rookie with a heavy, over-filled 1 litre glass culture flask raises the potential for tragedy tremendously. The shaker was packed with flasks nurturing precious cultures from a number of different labs. Our rookie, puffed with the excitement of growing his first scaled-up culture of his first ever isolated clone strides toward the shaker, pushes the stop button, opens the door and places his flask onto the sticky stuff, making sure it is well stuck down.

The problem with that sticky stuff is that you can never be sure that anything is well stuck down, especially a heavy, overfilled flask and as the rookie left the room his flask was already working it’s way free of it’s anchor. Within minutes his flask had tipped over and his precious culture, which had once held so much promise, was ruined.

The other problem with that sticky stuff is that it loses its stickiness when it gets wet. As his culture medium poured across the shaker platform, it tragically loosened of all of the other culture flasks, condemning them to the doom that lay beneath and ruining the hard work of their owners. One mistake, 30 ruined experiments, 10 angry people.

4. Centrifuge destruction. Few single pieces ordinary lab equipment are more expensive, or more open to damage by those inexperienced in their use, than ultra-centrifuges. The big ones I mean. Confucius (or was it Yoda?) once said “Tubes in rotor spinning at 12,000 x g cannot be balanced by eye alone”. Unfortunately, a PhD rookie I once knew was not party to this undoubted wisdom. Happy that each of her glass centrifuge tubes were filled to “around the same level”, she cranked the machine up to 12,000 x g and went to have a relaxing coffee during the 30 minutes that the machine would do it’s job.

The machine did it’s job, dutifully forcing it’s motor toward the desired 12,000 x g. As the rotor speed increased, the destabilizing effect of the difference between the volumed in the tube became more and more significant. Normally these machines detect imbalances and stop before too much damage is done. For some reason, fate? murphy’s law? or maybe just that it was an old model?, the machine in question did not possess this ability and kept cranking up the revs until the force bent the axle, causing the rotor to destroy the inner drum of the centrifuge, creating a terrifying noise that alerted her lab colleagues to turn the machine off. Returning from her coffee break to continue her experiment, our PhD rookie was horrified by the sight that greeted her. The Force was obviously not strong in her.

Please save future rookies from fates such as these – remember to add your own tales of disaster in a comment below.

Photo: Sea Turtle

31 Comments

Leave a Comment

You must be logged in to post a comment.

A dynamic chemical reaction is not the same in formula form as it is in a true space time reality.

As a senior scientist I’ve taken up a unique practice shown to me by a Auto Body Shop owner. Before interviewing a prospect to work with the team I lay a broom across the doorway. Most will notice it but simply step over it. Only a few will pick up the broom and put it in a safe place.(this test allows me to weed out rookie mistakes because the ones that pick up the broom have that ability to see the possibility of error and will take steps to avoid it.)

Not securing the rotor after exchanging it with another one. Oops.

Some of the disasters which I have done:

1. While working under the laminar flow, using alcohol on your hands and then it catches fire. in order to stop the fire, another hand is used. Alas the other hand is also cleaned with alcohol. So think what will happen

2. Using molecular ladder instead of blue juice in the PCR reaction.

3. Using high melting point agarose instead of low melting point agarose for running gels.

See, if you use your pipette to do your innoculations like I do, that won’t happen. 😉

A couple things I’ve seen are less dramatic, but funny. Someone made up their liter of medium wrong and then poured the whole liter down the sink, or tried to, anyways. Had to call the plumber out for that one, and ended up with a U-shaped piece of LB agar.

Another guy poured out the dry ice packing his reagents into the sink, then tried to wash it down. Ended up breaking the trap beneath when it the water froze and expanded.

Still a different guy was getting some frozen cells out of the LN2 tank, but hadn’t stored them in o-ring vials, so some LN2 leaked in during storage and caused the vials to blow up in his face about 30 seconds or so after taking them out of the tank. They were patient-derived samples, too.

Then there was the crystal violet powder spill that they tried to clean up with wet paper towels…

RCF != RPM.

If you want 100,000 g in your ultracentrifuge, do not set it for 100,000 RPM. As with your #4, the overspeed disk in this case failed, and the rotor (rated for 41,000 RPM) blew at 48,000 RPM, making the 1000-pound ultracentrifuge merrily dance across the floor and converting the inside to iron filings.